|

Institute of Chemical Physics after A.B. Nalbandyan Division of Chemistry and Earth Sciences |

Development of a technology for synthesis by the hydride cycle method of titanium-based alloys (including Ti6Al4V alloy) for further application

| N | Investment project title | Development of a technology for synthesis by the hydride cycle method of titanium-based alloys (including Ti6Al4V alloy) for further application | |

| 1. | Sector | Areas of application: structural materials for aerospace and ground machine building, chemical and food industries, medicine, etc. |

|

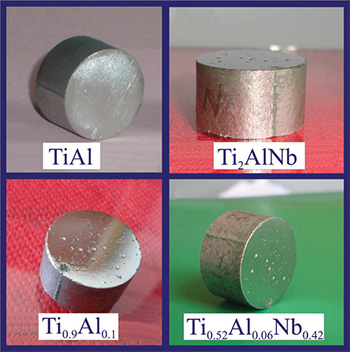

| 2. | Project description | The goal of the project is the realization of the practical possibilities of in principle a new method for titanium based alloys synthesis developed at Laboratory of technology of SHS processes of IChPh of NAS RA (hydride cycle method: HC – a method of synthesis of alloys from the hydrides of respective metals), defining of optimal technological parameters for forming alloys on the base of titanium (including Ti6Al4V alloy), development of new highly effective resource-saving technologies for synthesis of alloys with high exploitation characteristics. These technologies are simple, do not require the subsequent stage of hot deformation and permit producing of low-cost details of commercial interest from titanium alloys. The HC method has significant advantages over the traditional ones: decreased operation temperatures (600-1200°C instead of 1800-2600°C) and duration of the process (1.5-2 hours instead of tens of hours); it is a one-stage and non-waste; the availability of a highly efficient, energy-saveing SHS process, providing relatively inexpensive initial materials (hydrides and alloy powders). |

|

| 3. | Project implementation period | 24 months | |

| 4. | Project location | A. Nalbandyan Institute of Chemical Physics of NAS RA | |

| 5. | Project overall cost (USD) | 160.000 | |

| 6. | Required investments (USD) | 160.000 | |

| 7. | Own funds (USD) | It is offered to create a pilot production of details, wares, powders from the titanium alloys (including Ti6Al4V alloy) using the main equipment: SHS reactors, laboratory equipment for HC implementation, vacuuming down to 10-3 Torr , heating up to 1000-1 | |

| 8. | Creation of jobs | At the beginning of the project | At the end of the project |

| 12 | 16 | ||

| 9. | Payback period | 36 months | |

| 10. | Annual profitability index | Profitability on preliminary calculations is of 20-30% | |

| 11. | Detailed costs | Vacuum furnace, special molds, salaries for participants, etc. |

|

| 12. | Offer to investor | It is proposed to have negotiation on further cooperation in the case of the introduction of the technology into the industry. |

|

| 13. | Contact details | Seda Dolukhanyan, Head of the Laboratory of A.Nalbandyan Institute of Chemical Physics of NAS RA |

|

|

| Titanium aluminides produced by the HC method |

General Page - About Academy - Divisions - Organizations - Members - Contact us - Structure - Presidium Members

Documents - Innovation Proposals - Publications - Funds - Conferences - Competitions - International cooperation

Youth programs - Photogallery - Videogallery - Web Resources Other Academies - "Gitutyun" newspaper - "In the World of Science" Journal

Publications in Press - Notices - Anniversaries - Universities - News - Scientific Results - Scientists of the Diaspora

Young Scientist Tribune - Our Honored Figures - Announcements - Sitemap - Search